Boosting Baling Machine Performance with Bonded Textile Strapping

Baling machines play a crucial role in the recycling and waste management industries by compressing and bundling materials for easier handling, storage, and transportation. The choice of strapping material significantly impacts the efficiency and reliability of these machines. Bonded textile strapping has gained popularity as a superior alternative to steel and plastic strapping due to its high strength, flexibility, and cost-effectiveness. This article explores how bonded textile strapping enhances the performance of baling machines and contributes to improved operational efficiency.

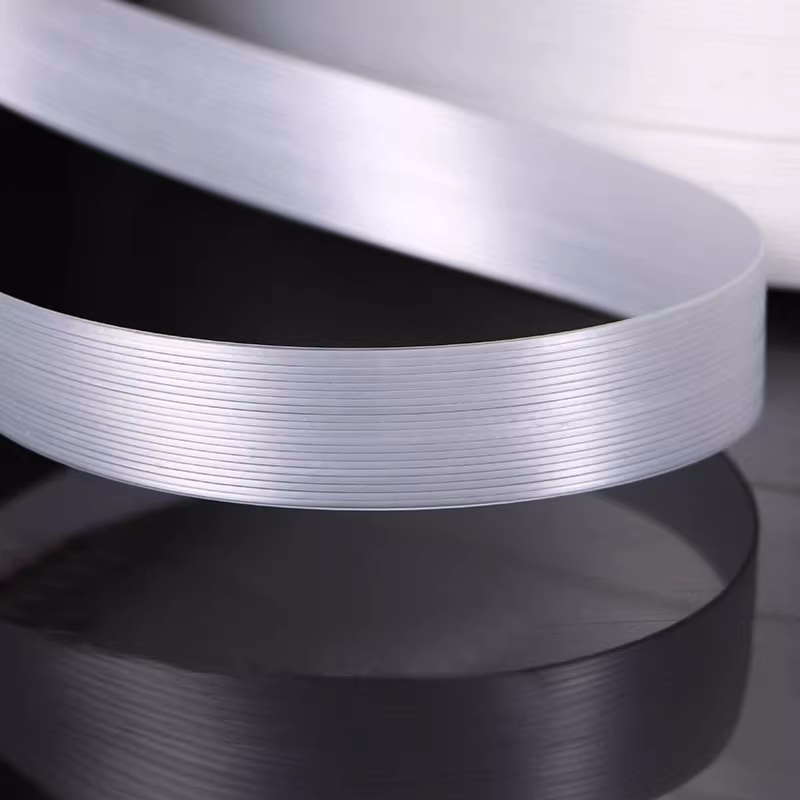

Understanding Bonded Textile Strapping

Bonded textile strapping is made from high-tensile polyester fibers that are bonded together to form a strong and durable strapping solution. Unlike steel strapping, which is rigid and prone to rust, or plastic strapping, which can be brittle, bonded textile strapping offers a combination of strength, flexibility, and resilience. It is designed to handle heavy loads while maintaining its integrity under various environmental conditions.

How Bonded Textile Strapping Improves Baling Machine Performance

1. Enhanced Load Stability and Compression Retention

Baling machines compress materials such as paper, plastics, textiles, and metal scraps into compact bales. To maintain their shape and stability, strong and reliable strapping is essential. Bonded textile strapping provides excellent tension retention, ensuring that bales remain tightly secured throughout storage and transportation. Unlike traditional strapping materials that can loosen over time, bonded textile strapping maintains its grip, reducing the risk of bale deformation or breakage.

2. Increased Safety and Worker Protection

Steel strapping is known for its sharp edges, which pose a risk of injury to workers during application and removal. Additionally, steel straps can snap under high tension, leading to dangerous recoil. Bonded textile strapping eliminates these hazards by offering a safer, lightweight alternative. Its soft texture and flexible nature make it easier to handle, reducing the likelihood of cuts and other injuries.

3. Superior Shock Absorption and Impact Resistance

During transportation, bales are subject to movement, vibrations, and impacts that can compromise their integrity. Bonded textile strapping has excellent elasticity, allowing it to absorb shocks and distribute tension evenly across the bale. This feature prevents strap breakage and ensures that materials remain securely bundled, even in demanding logistical conditions.

4. Resistance to Environmental Factors

Recycling facilities often operate in environments where exposure to moisture, extreme temperatures, and chemicals is common. Unlike steel strapping, which is susceptible to rust, bonded textile strapping is highly resistant to corrosion and weather-related damage. It also withstands exposure to UV rays and harsh chemicals, making it a long-lasting and dependable choice for baling applications.

5. Faster and More Efficient Application

Bonded textile strapping is designed for ease of use, allowing workers to apply and secure bales more efficiently. Unlike steel strapping, which requires heavy-duty tools and specialized safety equipment, bonded textile strapping can be tensioned and fastened using simple hand tools or automatic strapping machines. This efficiency reduces downtime and increases overall productivity in recycling and waste management facilities.

6. Cost Savings and Operational Efficiency

Using bonded textile strapping can lead to significant cost savings for businesses. It is more affordable than steel strapping and requires less maintenance, as it does not rust or become brittle over time. Additionally, its lightweight nature reduces shipping costs and minimizes strain on handling equipment. By improving the efficiency of baling operations, bonded textile strapping contributes to lower operational expenses and higher profitability.

7. Eco-Friendly and Sustainable Strapping Solution

Sustainability is a growing concern in the recycling industry, and bonded textile strapping aligns with environmental goals. Unlike plastic strapping, which contributes to plastic waste, bonded textile strapping is made from recyclable polyester fibers. Many bonded strapping products can be reused or repurposed, reducing overall waste generation. This makes it an eco-friendly choice for businesses looking to minimize their environmental impact.

Applications of Bonded Textile Strapping in Baling Machines

Bonded textile strapping is widely used in various industries that rely on baling machines for material compression and bundling. Some key applications include:

- Paper and Cardboard Recycling – Securing compressed paper and cardboard for efficient transport to recycling facilities.

- Plastic Waste Management – Bundling plastic materials, such as bottles and packaging, to facilitate recycling.

- Metal Scrap Recycling – Holding together lightweight metal scraps to prevent scattering and improve handling.

- Textile Waste Processing – Compressing fabric and clothing waste into bales for easier storage and transport.

Conclusion

Bonded textile strapping has revolutionized the baling process by offering a safer, more efficient, and cost-effective solution for securing compressed materials. Its high tensile strength, shock absorption, resistance to environmental factors, and ease of use make it an ideal choice for recycling and waste management facilities. By integrating bonded textile strapping into their baling operations, businesses can enhance machine performance, improve worker safety, and contribute to a more sustainable waste management system. As the industry continues to evolve, bonded textile strapping will remain a key component in optimizing baling machine efficiency and overall operational success.