How Woven Polyester Banding Enhances Load Stability and Safety

In logistics and industrial packaging, ensuring load stability and safety is a top priority. Improperly secured loads can lead to product damage, transportation hazards, and financial losses. Woven polyester banding has emerged as a superior strapping solution, offering strength, flexibility, and reliability for securing goods during transport and storage. This article explores how woven polyester banding enhances load stability and safety, making it an ideal choice for various industries.

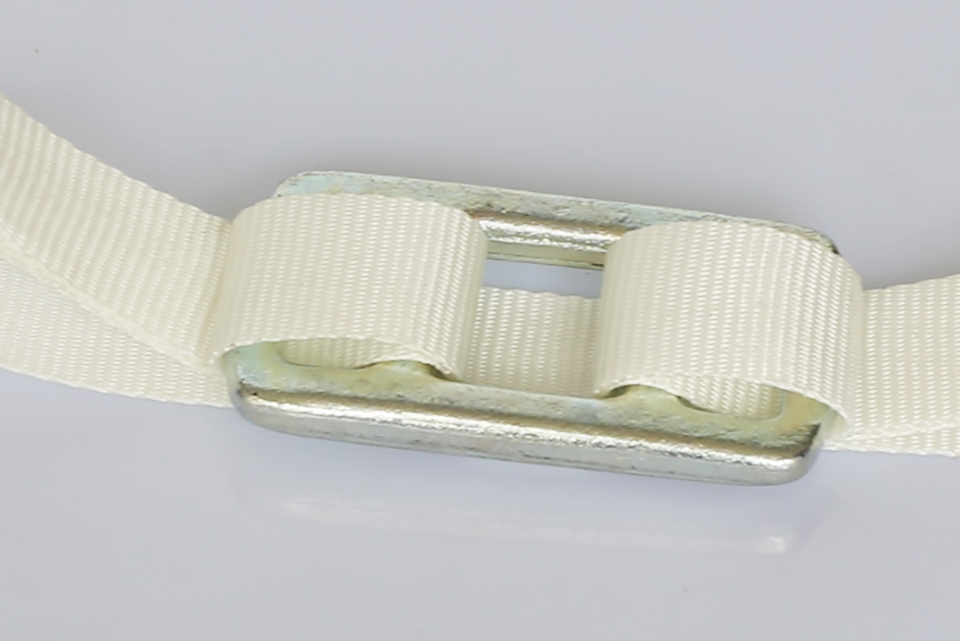

1. Understanding Woven Polyester Banding

Woven polyester banding is a type of industrial strapping made from high-strength polyester fibers woven together for enhanced durability. Unlike rigid steel strapping or brittle plastic alternatives, woven polyester banding combines flexibility with superior tensile strength. It is commonly used in industries such as logistics, construction, and manufacturing to secure heavy loads, ensuring they remain stable during transit.Key Characteristics of Woven Polyester Banding:

-High tensile strength, comparable to steel strapping

-Excellent shock absorption and flexibility

-Lightweight and easy to handle

-Resistant to moisture, UV rays, and harsh environmental conditions

-Safer to use compared to steel strapping

2. Improving Load Stability

Load stability is crucial for preventing cargo shifts and ensuring products arrive undamaged. Woven polyester banding enhances stability in several ways:

A. High Tensile Strength for Heavy Loads

Woven polyester banding is designed to withstand significant tension without snapping. Its high tensile strength allows it to secure heavy and bulky loads, including:

-Construction materials such as timber, bricks, and steel pipes

-Industrial equipment and machinery

-Palletized goods in warehouses and distribution centers

Unlike traditional plastic strapping, which may break under excessive tension, woven polyester banding maintains its integrity even under high loads, preventing unwanted movement.

B. Shock Absorption for Better Stability

One of the key advantages of woven polyester banding is its ability to absorb shocks and vibrations. During transportation, loads are often subjected to:

-Road vibrations

-Sudden stops and turns

-Turbulence in air or sea freight

Unlike steel strapping, which is rigid and can damage goods when subjected to impact, woven polyester banding stretches slightly under tension. This elasticity helps absorb shocks, reducing the risk of cargo shifting or breaking during transport.

C. Non-Slip Surface for Better Grip

The woven texture of polyester banding creates a non-slip surface that grips onto the load securely. This prevents slippage, especially when bundling smooth or irregularly shaped products. When combined with the right tensioning tools, woven polyester banding provides a firm hold, further enhancing stability.

3. Enhancing Safety in Packaging and Transportation

In addition to improving load stability, woven polyester banding significantly enhances workplace and transportation safety.

A. Reduced Risk of Worker Injuries

Steel strapping, while strong, poses significant safety risks:

-Sharp edges that can cause cuts and injuries

-Dangerous recoil when cut under tension

-Heavy weight, making handling more difficult

Woven polyester banding eliminates these hazards. It is soft and flexible, reducing the risk of injuries when workers handle it. Additionally, it does not snap back when cut, making it much safer to remove from secured loads.

B. Preventing Cargo Damage

When transporting fragile or delicate goods, traditional steel strapping can be too rigid, leading to:

-Surface scratches and dents

-Excessive pressure that damages packaging

-Difficulty in securing odd-shaped items

Woven polyester banding provides a gentler yet firm hold, reducing the chances of product damage while maintaining load security. This is particularly beneficial for industries that transport sensitive materials such as glass, electronics, and automotive parts.

C. Resistance to Environmental Factors

Unlike steel strapping, which can rust and degrade over time, woven polyester banding is resistant to:

-Corrosion and oxidation

-Moisture and humidity

-UV exposure and temperature fluctuations

This makes it an excellent choice for outdoor storage, marine transport, and long-distance shipping, ensuring that loads remain securely strapped regardless of environmental conditions.

4. Cost-Effectiveness and Efficiency

In addition to safety and stability, woven polyester banding offers cost savings and operational efficiency.

A. Lower Material and Handling Costs

Compared to steel strapping, woven polyester banding is more cost-effective due to:

-Lower material costs

-Reduced risk of damage to goods (saving on replacement and repairs)

-Less need for heavy-duty tools and machinery for application

Moreover, its lightweight nature reduces shipping costs, especially for bulk shipments.

B. Reusability and Sustainability

Unlike single-use plastic strapping, woven polyester banding can often be reused multiple times, making it a more sustainable packaging solution. Some key benefits include:

-Less waste generated

-Lower disposal costs

-Eco-friendly alternative to steel and plastic strapping

By choosing woven polyester banding, businesses can reduce their carbon footprint while maintaining secure packaging solutions.

5. Easy Application and Versatility

Another reason woven polyester banding is widely used is its ease of application. It can be used with:

-Manual tensioners and buckles

-Pneumatic and battery-powered strapping tools

-Friction weld and heat-sealing technology

Its versatility makes it suitable for securing loads in various industries, including:

-Logistics and freight transportation

-Warehousing and distribution

-Agriculture and timber industries

-Automotive and heavy machinery sectors

Conclusion

Woven polyester banding is an excellent choice for enhancing load stability and safety in packaging and transportation. Its high tensile strength, flexibility, and shock-absorbing properties ensure that loads remain secure during transit. Additionally, it offers significant safety advantages over steel strapping, reducing the risk of worker injuries and product damage.

From cost savings to environmental benefits, woven polyester banding provides a reliable, efficient, and sustainable packaging solution. Whether securing heavy industrial materials or delicate shipments, businesses can rely on woven polyester banding to improve safety, stability, and overall logistics efficiency.