Maximize Efficiency with a WG Strap Set: How All-in-One Kits Simplify Packaging Tasks

In the fast-paced worlds of logistics, warehousing, construction, and manufacturing, efficiency isn't just a goal—it's a necessity. Every minute saved in packaging, bundling, or securing goods translates directly to lower operational costs, faster throughput, and improved customer satisfaction. Yet, a surprising amount of time and energy is often wasted on a seemingly simple process: strapping. This is where the strategic adoption of an all-in-one WG Strap Set transforms the workflow, moving from a fragmented, problem-prone task to a streamlined, foolproof operation. Let's explore how these comprehensive kits dismantle inefficiencies and supercharge your packaging productivity.

1. Eliminating the "Search and Gather" Time Sink

The traditional approach to manual strapping involves maintaining an inventory of separate components: reels of strapping, boxes of buckles (seals), and tools like tensioners and cutters. When a task arises, an operator must locate each item, ensuring compatibility in size (e.g., 13mm vs. 16mm) and type. This "search and gather" phase is a silent productivity killer. A WG Strapping Combo Kit, like the BSTMELT starter kits, eradicates this step entirely. The kit arrives as a cohesive unit, with perfectly matched strapping lengths, buckles, and often a basic tool, all calibrated to work together seamlessly. The operator grabs a single kit and is immediately ready for work, turning what was a 5-10 minute preparation chore into a 10-second action. This efficiency gain is magnified across multiple tasks and operators throughout the day.

2. Guaranteed Compatibility and Optimal Performance

Mismatched components are a major source of frustration and failure. Using a buckle not rated for the strap width or material can lead to catastrophic slippage and load failure during transit. An all-in-one set is engineered as a system. The WG strapping is specifically designed to interface with the buckles provided, ensuring optimal friction grip and tensile strength. This guaranteed compatibility removes the guesswork and risk from the operator's hands. They can trust that the system will perform as intended, securing even heavy, irregular loads like steel pipes or timber stacks. This reliability prevents costly redos, damaged goods, and the safety hazards associated with strap failure.

3. Portability and Operational Flexibility

Efficiency isn't just about speed; it's about agility. Many packaging and bundling needs are decentralized—a pallet needs securing in a remote corner of the warehouse, materials require bundling on a construction site, or goods need stabilizing in a loading bay. Carrying separate heavy reels of strapping, a bucket of buckles, and tools is cumbersome and discourages mobility. A WG Strap Set is inherently portable. Designed for manual operation, these kits are lightweight and consolidated. An operator can effortlessly carry several kits to the exact point of need, enabling "just-in-time" securing without multiple trips. This mobility ensures that the packaging process doesn't bottleneck at a fixed station but flows dynamically with the movement of goods.

4. Reducing Complexity and Training Time

Complex processes require extensive training and are prone to user error. A comprehensive WG kit simplifies the strapping procedure to its most essential steps: position the strap, thread the buckle, tension, and secure. The pre-measured strap lengths (common in starter kits) also help in standardizing application and reducing waste. This simplicity drastically shortens the learning curve for new employees. They can be trained and become proficient in secure bundling in minutes, not hours. Furthermore, it standardizes the quality of output across your team; everyone is using the same optimized system, leading to consistent, reliable results regardless of the operator's prior experience.

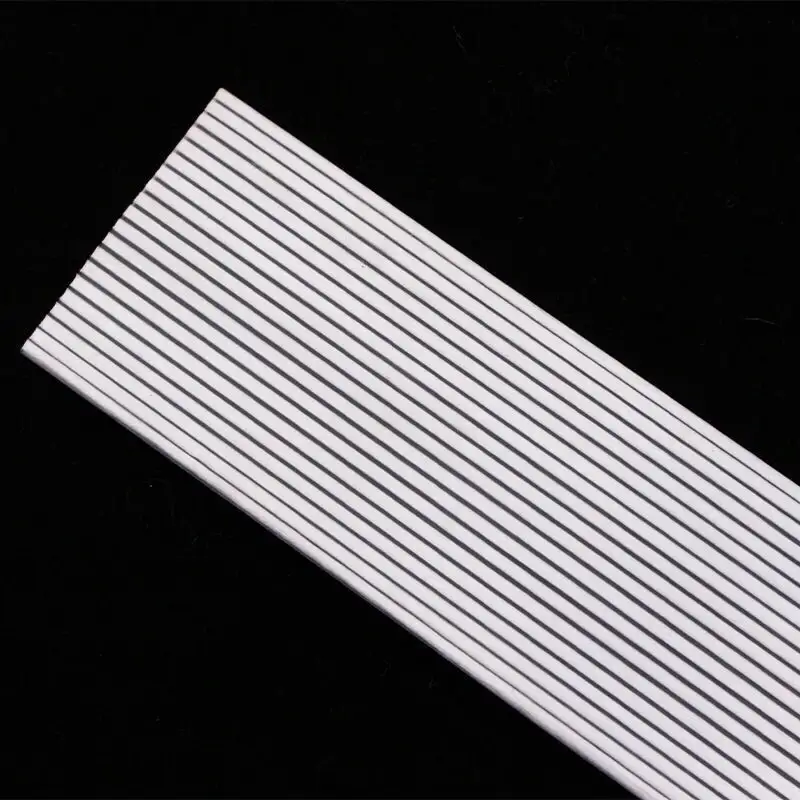

5. The Hidden Efficiency of Superior Material: WG Strapping

The core of the kit's efficiency lies in the WG strapping itself. Its unique composite fiber construction offers advantages that save time and trouble down the line:

-Weather Resistance: Unlike steel that rusts or some plastics that become brittle, WG strapping maintains consistent tension and integrity in humidity, rain, or temperature extremes. This means goods secured indoors or in a warehouse won't arrive with loosened, failed straps if they encounter moisture during transport. You secure it once, confidently.

-Safety & Damage Prevention: The soft, non-metallic surface will not scratch, dent, or damage sensitive product finishes. This eliminates the need for additional protective corners or padding, simplifying the packing process. Crucially, it also removes the risk of operator lacerations from sharp metal edges, preventing workplace incidents that cause downtime, training of replacements, and administrative burdens.

-Ease of Handling & Disposal: WG strapping is lighter and more flexible than steel, making it easier and faster to handle. At the destination, it can be easily cut with standard cutters and is often recyclable, simplifying disposal compared to sharp, tangled metal strapping.

Conclusion: A Systemic Upgrade for Tangible Gains

Viewing a WG Strap Set as merely a collection of tools is to miss its profound impact. It is a packaging system upgrade that targets and eliminates multiple sources of waste: time waste in gathering components, material waste in incompatibility, labor waste in complex procedures, and risk waste in potential damage and injury.

For businesses looking to streamline operations, reduce overheads, and empower their workforce, the choice is clear. By investing in an all-in-one solution like the BSTMELT WG Strapping Combo Kit, you're not just buying straps and buckles—you're buying efficiency, reliability, and simplicity. You enable your team to focus on the task itself, not the logistics of the tools, thereby truly maximizing efficiency in every packaging task, from the warehouse floor to the final delivery point.