Corded Strapping Techniques: Ensuring Safety and Stability in Transit

In the world of logistics and packaging, securing loads for transport is a critical task. The importance of keeping goods intact and stable during transit cannot be overstated, as it directly impacts product quality, customer satisfaction, and operational efficiency. Among various strapping methods available, **corded strapping** stands out for its unique combination of strength, flexibility, and safety. In this article, we delve into the essential techniques for using corded straps effectively to ensure the safety and stability of goods during transport.

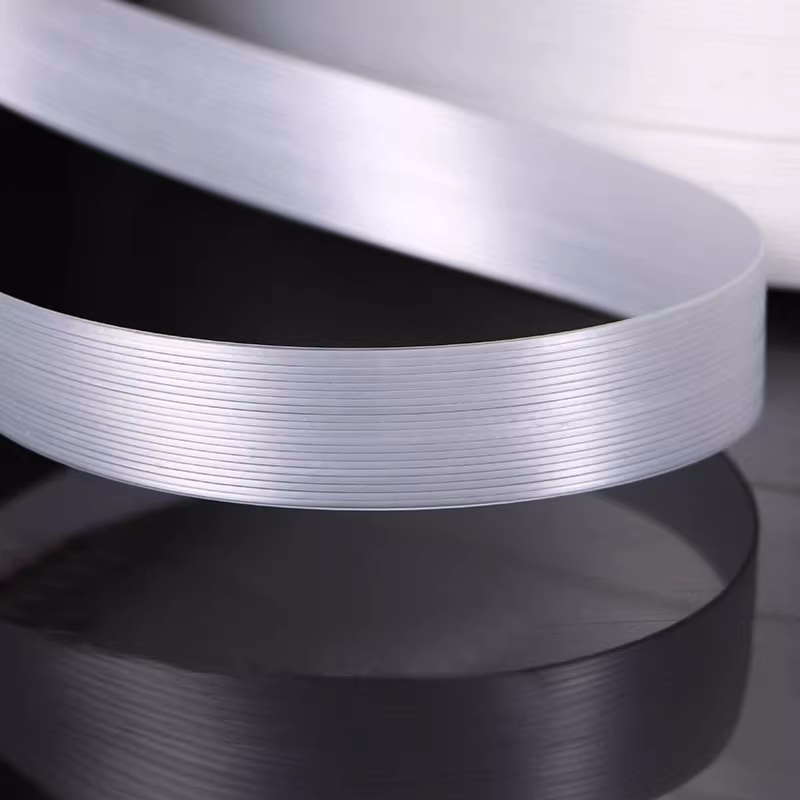

What Is Corded Strapping?

Corded strapping, also known as polyester cord strapping, is a high-strength strapping solution made from polyester fibers. Unlike traditional steel or polypropylene straps, corded straps are lightweight, easy to handle, and resistant to corrosion. They offer a safer and more versatile alternative for securing heavy or irregularly shaped loads.

Corded straps come in two main types:

1. Woven Cord Strapping:Features a cross-weave design for maximum durability.

2. Composite Cord Strapping:Coated with polypropylene for added protection against abrasion.

Both types are designed to absorb shock and maintain tension, making them ideal for a wide range of applications.

Key Benefits of Corded Strapping

Before diving into specific techniques, it's important to understand why corded strapping is favored by many industries:

- High Tensile Strength:Corded straps can handle heavy loads without breaking.

- Flexibility: They easily adapt to different shapes and sizes, ensuring a secure fit.

- Shock Absorption:The material stretches slightly under pressure, absorbing impacts during transit.

- Lightweight and Safe:Unlike steel straps, corded straps do not have sharp edges, reducing the risk of injury.

- Ease of Use:They can be tensioned and sealed manually or with tools, simplifying the strapping process.

Essential Techniques for Using Corded Straps

To maximize the benefits of corded strapping, it is crucial to apply proper techniques. Here are the key steps to ensure safety and stability:

1. Select the Right Strap Type and Size

Choose a corded strap based on the weight and nature of your load. Woven straps are ideal for heavy loads, while composite straps work well for items that require extra surface protection. Ensure the strap width and tensile strength are appropriate for your application.

2. Prepare the Load for Strapping

Before applying the strap, arrange the load on a stable surface. For palletized goods, ensure that the items are stacked evenly and tightly. Wrapping the load with stretch film can add an extra layer of stability.

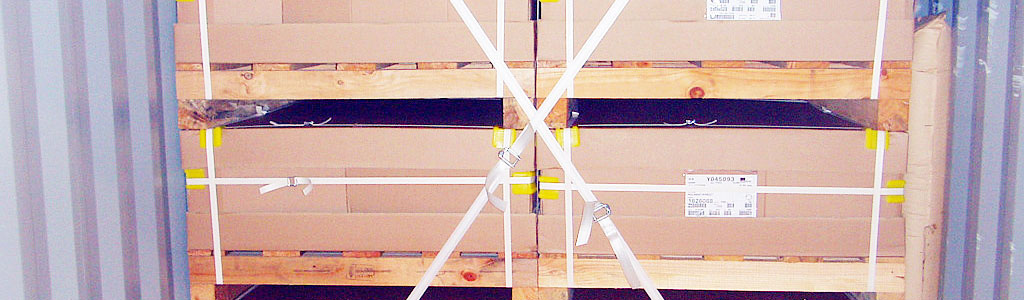

3. Position the Strap Correctly

Place the corded strap around the load, ensuring that it lies flat and does not twist. For optimal stability, position the straps at key points, such as the center and corners of the load.

4. Use Proper Tensioning Techniques

Tensioning is critical for securing the load. Use a manual or battery-operated tensioner to apply consistent force, ensuring the strap is tight but not overly stretched. Over-tensioning can damage the strap or the goods, while under-tensioning may lead to instability.

5. Secure the Strap with a Buckle or Seal

Corded straps are typically fastened using metal or plastic buckles. Thread the strap through the buckle, creating a secure loop. For added strength, tie a simple knot after threading. Ensure the buckle is positioned tightly to prevent slippage during transit.

6. Inspect the Strapping Job

Once the straps are in place, inspect the load for any loose ends or uneven tension. Adjust as needed to ensure the straps are evenly distributed and the load is fully secure.

7. Label and Mark the Load

For ease of handling and tracking, label the strapped load with relevant details such as weight, destination, and handling instructions.

Advanced Tips for Enhanced Safety and Stability

- Double-Strapping Heavy Loads:For exceptionally heavy items, consider using two or more straps to distribute the tension evenly.

- Cross-Strapping for Irregular Shapes:For irregularly shaped goods, apply straps in a crisscross pattern to improve stability.

- Regular Inspection: During transit, inspect the straps periodically to ensure they remain tight and intact. This is especially important for long-distance shipments.

- Training Your Team: Provide training to staff on proper strapping techniques to minimize errors and ensure consistent results.

Common Mistakes to Avoid

Even with the best materials, improper strapping techniques can compromise load security. Avoid these common mistakes:

- Using the Wrong Strap Type:Always choose a strap suited to the load's weight and nature.

- Incorrect Buckle Application:Improperly secured buckles can loosen, leading to instability.

- Overloading Straps:Exceeding the tensile strength of a strap can cause it to break under pressure.

- Skipping Load Preparation:Unevenly stacked loads can shift during transit, even with proper strapping.

Why Corded Strapping Is the Future of Secure Transport

As industries prioritize safety, efficiency, and sustainability, corded strapping offers a compelling solution. Its versatility, ease of use, and eco-friendly properties make it a preferred choice across sectors such as construction, manufacturing, and logistics.

By mastering corded strapping techniques, businesses can ensure that their goods reach their destination intact, minimizing the risk of damage and reducing operational costs.

Conclusion

Corded strapping is more than just a method for securing loads—it’s a critical component of safe and efficient logistics. By following the techniques outlined above, companies can harness the full potential of this innovative strapping solution. Whether you're shipping heavy machinery or delicate goods, proper corded strapping practices will ensure that your products arrive safely, every time.