Hot Melt Polyester Strapping: Applications, Advantages, and Benefits

In the world of packaging and load securing, one material stands out for its versatility, strength, and reliability: Hot Melt Polyester Strapping. Often referred to as **BALESTRAP** when used in baling applications, this type of strapping is gaining widespread use in various industries for its ability to secure, bundle, and protect goods during storage, transit, and recycling processes. Whether used for securing large, awkward products like drums or packaging goods that are being compressed into bales, hot melt polyester strapping is essential for ensuring that materials stay intact and secure throughout their journey.

This article will explore the benefits, applications, and advantages of hot melt polyester strapping, explaining why it has become a go-to choice in industries ranging from waste management to shipping, packaging, and manufacturing.

What is Hot Melt Polyester Strapping?

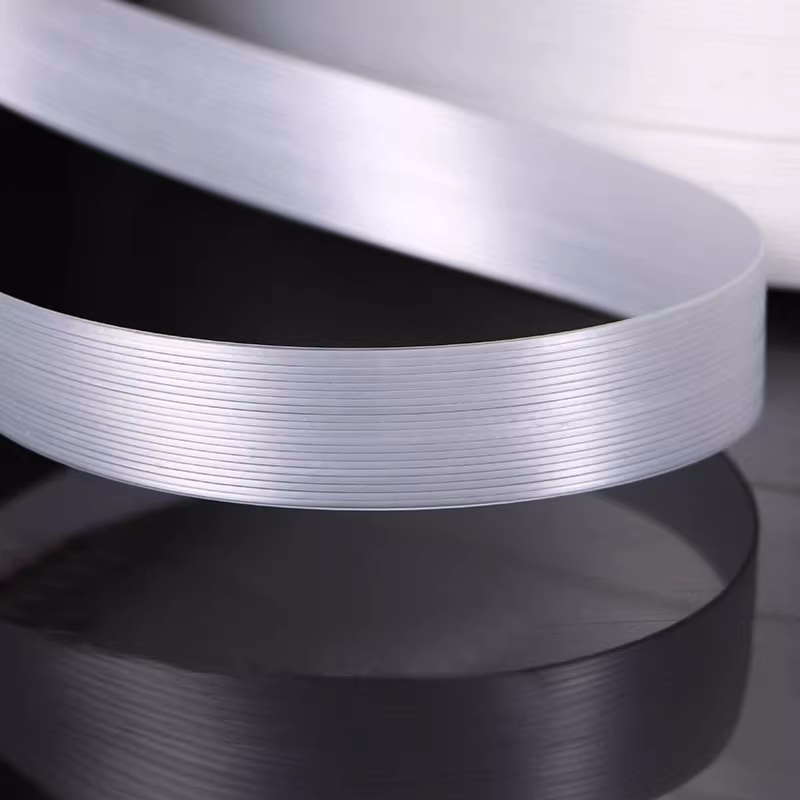

Hot Melt Polyester Strapping is a form of textile strapping made from polyester yarns that are glued together using a hot melt adhesive. This adhesive binds the fibers in such a way that it enhances the strength and integrity of the strapping. The result is a durable, flexible strapping that can be used for a wide range of applications, including securing compressed waste materials in baling machines and securing large, bulky products.

There are two main versions of hot melt polyester strapping: one produced on a 76mm core for standard packaging purposes and another on a 63mm core, typically used for baling presses. It is designed to handle the demands of packaging applications and load securing needs that require extra strength and durability.

Hot melt polyester strapping is available in a variety of sizes, and it can be used in both manual and pneumatic devices, making it adaptable to various handling environments. It is a favorite for applications requiring a flexible, strong, and reliable strapping material.

Key Applications of Hot Melt Polyester Strapping

1. Baling Applications

One of the most common uses of hot melt polyester strapping is in baling operations, particularly for waste management and recycling industries. The product, often referred to as **BALESTRAP**, is ideal for compressing waste materials such as paper, plastic, textiles, and cardboard into bales. Once the material is compressed, the hot melt polyester strapping secures the bales, keeping them intact during storage and transportation. This is particularly important for recyclers, as loose or poorly secured materials can lead to inefficiency and contamination.

2. Securing Large and Bulky Products

Hot melt polyester strapping is also used to secure large, awkwardly shaped products such as drums, pallets, and containers. In such applications, it is commonly used in conjunction with heavy-duty steel buckles. These buckles allow the strap to be re-tensioned if the product settles or shifts, ensuring the goods remain secure throughout the transport process. The versatility of hot melt polyester strapping makes it suitable for industries like logistics, shipping, and manufacturing, where large or oddly shaped products are often moved.

3. Outdoor Applications in the Wood Industry

One of the unique features of hot melt polyester strapping is its ability to withstand outdoor conditions. This makes it particularly useful in the wood industry, where materials are exposed to various environmental elements. Hot melt polyester strapping is waterproof, making it an excellent choice for securing timber, logs, and wood products that are stored or transported outdoors. The material can endure rain, moisture, and varying temperatures, ensuring it remains intact even in harsh conditions.

4. Load Securing and Heavy-Duty Packaging

Hot melt polyester strapping is also widely used for securing heavy loads during transportation. For instance, in the transportation of construction materials, machinery, and large bulk items, hot melt polyester strapping can be used to secure loads to pallets or trucks. The high tensile strength and ability to be re-tensioned at any time make it ideal for securing heavy products during long-distance shipping. Additionally, the strong adhesive surface of the strapping ensures that the strap remains tight, providing a high level of security.

Advantages of Hot Melt Polyester Strapping

1. Soft and Flexible

One of the standout characteristics of hot melt polyester strapping is its softness and flexibility. Unlike steel or other rigid materials, hot melt polyester is gentle on packaged goods, preventing damage to the goods and cardboard. This is especially important in industries where fragile items need to be securely packaged without the risk of scratches or abrasions. Its soft material, without sharp edges, ensures that there is no damage during handling or transport.

2. Re-Tensioning Capabilities

Another significant benefit of hot melt polyester strapping is its ability to be re-tensioned. If the volume of packaged goods decreases over time due to settling or compression, the strap can be tightened again to maintain a secure hold. This re-tensioning feature makes hot melt polyester strapping highly adaptable and cost-effective, as it eliminates the need for replacing straps due to minor shifts in the load.

3. Strong Hold and High System Strength

Despite its flexibility, hot melt polyester strapping is incredibly strong and durable. Its sticky surface provides a secure grip, which helps to ensure that the strap holds the materials tightly. This strong hold is a critical aspect when transporting goods or securing heavy loads. The high system strength, combined with high elasticity and memory effect, makes hot melt polyester strapping ideal for maintaining load integrity during long-distance shipping or storage.

4. Waterproof and Weather-Resistant

Hot melt polyester strapping is waterproof and resistant to weather conditions, which is why it is commonly used in industries like the wood and construction industries. Whether it’s exposed to moisture, rain, or UV light, the strapping maintains its strength and functionality. This quality ensures the strap’s durability in challenging environments, providing a longer-lasting solution for securing goods.

5. Cost-Effective and Easy to Handle

Hot melt polyester strapping is both economical and practical to use. It can be processed manually or pneumatically, depending on the specific requirements of the application. This flexibility means it can be used in a variety of settings, from small-scale operations to large factories. Additionally, its ability to be knotted for in-house applications or smaller projects adds an extra layer of versatility and practicality.

6. No Additional Edge Protection Needed

Unlike other types of strapping that require additional edge protection, hot melt polyester strapping is soft enough to be used without the need for extra protection. This simplifies the process, reducing the need for additional materials and saving on costs.

7. Sustainable Production

Hot melt polyester strapping is produced in an efficient, resource-saving manner. The manufacturing process ensures that the strapping is consistently high in quality, which is essential for industries that require dependable and strong materials. Additionally, it is a recyclable product, aligning with the growing demand for sustainable packaging and waste management solutions.

Conclusion

Hot melt polyester strapping is a versatile, reliable, and cost-effective solution for a wide range of applications. From securing large products in shipping and logistics to bundling recyclable materials in baling operations, this strapping material excels in providing strength, flexibility, and ease of use. Its ability to withstand outdoor conditions, its re-tensioning capabilities, and its ability to protect goods without damage make it the ideal choice for industries across the globe.

Whether you're in the wood, recycling, packaging, or construction industries, hot melt polyester strapping offers numerous advantages that can enhance the efficiency and security of your operations. Investing in this high-quality strapping solution not only ensures the safe transport and storage of your goods but also aligns your business with sustainable practices.