How Baler Banding Improves Waste Management: A Focus on Cardboard and Plastic Compaction

In today’s waste management industry, efficient systems and processes are essential to handle the growing volumes of recyclable materials such as cardboard and plastic. One of the most significant innovations in the recycling and waste management sector is the use of **baler banding**. Baler banding, a method of using strong straps or bands to tightly bind waste materials into dense, secure bales, has revolutionized the way cardboard, plastic, and other materials are handled, transported, and stored. This technique plays a pivotal role in improving the overall efficiency and sustainability of waste management operations. In this article, we will explore how baler banding enhances waste management, focusing specifically on the compaction of cardboard and plastic waste.

What is Baler Banding?

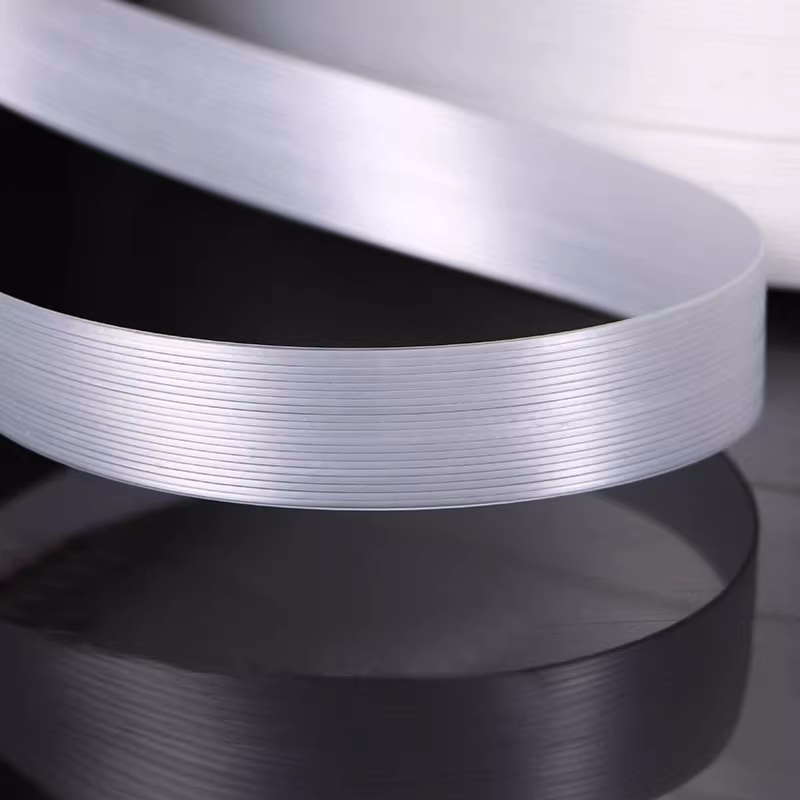

Baler banding involves using durable strapping material, often made from materials like **polyester**, **polypropylene**, or **composite fibers**, to compress waste materials into tightly bound bundles, known as bales. These bales are then easier to store, transport, and recycle, improving efficiency across the waste management process. The banding material is applied using a baling machine, which tightens the bands around the waste materials, compressing them into uniform shapes and sizes.

In the context of cardboard and plastic waste, baler banding has become indispensable. Both materials are lightweight and bulky, taking up significant space when not compressed. Without proper compaction, managing large volumes of waste would be a logistical challenge. This is where baler banding steps in to provide a cost-effective, space-saving solution.

The Role of Baler Banding in Cardboard and Plastic Waste Compaction

1. **Efficient Use of Storage Space**

In waste management facilities, space is often limited, and inefficient use of space can lead to operational inefficiencies. Without baling, cardboard and plastic waste can accumulate quickly, creating clutter and disorganization in the facility. Baler banding helps by compressing these materials into dense bales, which are much smaller in volume compared to loose, unbundled waste. As a result, storage space is optimized, allowing more materials to be stored in a smaller area.

Bales of cardboard and plastic waste can be neatly stacked, making better use of vertical space and reducing the overall footprint of waste storage areas. This organization not only improves the storage of recyclables but also enhances overall workflow, as workers can quickly access materials without having to sift through piles of disorganized waste.

2. **Improved Transportation and Handling**

Another significant advantage of baler banding is its impact on the transportation and handling of recyclable materials. Cardboard and plastic waste, in their loose form, can be unwieldy and difficult to move. When handled improperly, they can spill, create litter, or become contaminated, making the recycling process less effective. By compressing these materials into tightly bound bales, baler banding ensures that they stay intact during transport.

Whether the waste is being moved within a facility or transported to an off-site recycling center, bales of cardboard and plastic are much easier to handle. They are more stable and secure, reducing the risk of accidents, spills, or damage. Baler banding also simplifies the loading and unloading process, as bales can be stacked and organized more efficiently, enabling faster and safer handling with forklifts, pallet jacks, or conveyor belts.

3. **Cost-Effectiveness**

Waste management facilities are often looking for ways to reduce operational costs, and baler banding provides a cost-effective solution. By compacting cardboard and plastic waste into smaller, denser bales, facilities can increase their storage capacity and reduce the need for frequent waste pickups. This leads to savings on transportation and disposal costs, as fewer trips are required to move the bales to recycling plants or landfills.

Moreover, the use of baler banding machines, especially automated systems, reduces the amount of manual labor required for waste compaction and handling. Workers no longer need to spend time manually bundling and organizing waste materials. Instead, they can focus on other tasks, improving overall productivity and reducing labor costs.

4. **Minimized Environmental Impact**

One of the most significant advantages of baler banding in waste management is its positive environmental impact. Cardboard and plastic waste are some of the most common materials in landfills, and their proper recycling is essential to reducing overall waste and conserving natural resources. Baler banding enhances the recycling process by creating compact, uniform bales that are easier to transport to recycling centers.

By improving the efficiency of waste management, baler banding helps reduce the carbon footprint of transporting and processing recyclables. Bales are more efficient to transport, requiring fewer trips and less fuel. Additionally, many of the materials used for baler banding, such as polyester and polypropylene, are recyclable themselves, contributing to a more sustainable system by reducing waste and reusing materials in the recycling process.

5. **Improved Sorting and Recycling Efficiency**

Once waste materials are compacted and bound into bales, sorting and processing them becomes more efficient. When cardboard and plastic waste are loose and unorganized, it can be challenging to separate different types of recyclables or ensure that the materials are clean and uncontaminated. Bales of cardboard and plastic are easier to identify, manage, and separate during the recycling process.

The compact nature of baled waste also helps in reducing contamination. Contaminants such as food waste or liquids can be trapped and spread throughout unbundled recyclables, making it harder to recover usable materials. By using baler banding, recycling facilities can ensure that materials stay clean and pure, leading to a higher quality of recycled products and a more efficient recycling process overall.

6. **Safety Benefits**

Baler banding plays an important role in maintaining workplace safety in waste management facilities. When materials are left loose or poorly secured, there is a higher risk of accidents. For example, unbound plastic waste can slip and cause workers to trip, or cardboard could topple over and injure someone. By binding materials into stable, compact bales, baler banding reduces the chances of such accidents. Workers can move materials more safely, and the overall safety of the facility is improved.

Conclusion

Baler banding is a game-changer in waste management, particularly when it comes to handling cardboard and plastic waste. By compressing these materials into dense, secure bales, baler banding not only optimizes storage space and reduces transportation costs but also improves the efficiency of recycling operations. The environmental benefits are significant, as this process helps reduce the carbon footprint and increase recycling rates. Moreover, it offers cost savings, improved safety, and a more organized approach to waste management.

As waste management continues to grow in importance, especially with the rising need for sustainable solutions, the role of baler banding will only increase. Facilities that invest in baler banding systems can streamline their operations, improve productivity, and contribute to a greener, more efficient waste management ecosystem. For businesses seeking to enhance their waste management processes, incorporating baler banding is a smart, sustainable, and cost-effective solution.