The Benefits of Using Hot Melt Strapping in Compression Packing Applications

In the realm of industrial packaging, the utilization of effective strapping materials is paramount to ensure the safety, security, and integrity of goods during transportation and storage. Among the various strapping solutions available, hot melt strapping has emerged as a superior choice, particularly in compression packing applications. This article delves into the myriad benefits of using hot melt strapping, highlighting its unique properties and advantages that make it an indispensable tool in various industries.

Understanding Hot Melt Strapping

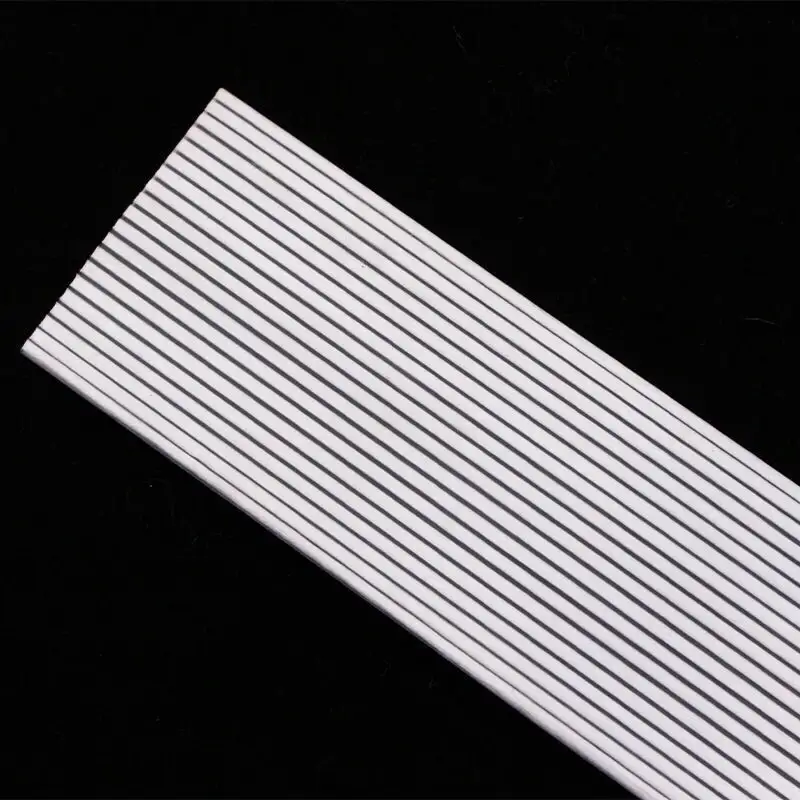

Hot melt strapping is a type of packaging material that utilizes the properties of thermoplastic resins. Unlike traditional strapping materials like steel, polyester, or polypropylene, hot melt strapping is applied in a molten state and solidifies upon cooling, forming a strong, durable bond. This process involves heating the strapping material to its melting point, applying it to the package, and allowing it to cool and harden, thereby securing the load.

Enhanced Strength and Durability

One of the most significant benefits of hot melt strapping in compression packing applications is its exceptional strength and durability. The molten thermoplastic resin forms a tight, cohesive bond with the packaged items, creating a secure hold that resists breaking and tearing. This robustness is particularly advantageous in applications where high compression forces are applied, such as in the packaging of heavy, bulky goods or in situations where the packages are subjected to rigorous handling and transportation conditions.

Moreover, hot melt strapping maintains its strength over a wide range of temperatures, making it suitable for use in extreme environments. Unlike some other strapping materials that may weaken or brittle in cold conditions, hot melt strapping remains flexible and resilient, ensuring consistent performance and reliability.

Cost-Effectiveness

Cost efficiency is another critical factor favoring the use of hot melt strapping. While the initial investment in hot melt strapping equipment may be higher, the long-term savings are substantial. Hot melt strapping materials are generally less expensive than traditional strapping options, such as steel or polyester, and the process of applying them is more streamlined and efficient.

Furthermore, hot melt strapping eliminates the need for additional hardware like buckles, clips, or seals, which further reduces costs. The elimination of these components also simplifies the packaging process, reducing labor time and enhancing productivity.

Environmental Sustainability

In today's world, environmental sustainability is a top priority for businesses and consumers alike. Hot melt strapping offers a sustainable packaging solution that aligns with these concerns. Thermoplastic resins used in hot melt strapping are often recyclable, and many manufacturers are actively developing eco-friendly formulations that reduce environmental impact.

Additionally, hot melt strapping generates minimal waste compared to traditional strapping methods. The molten resin adheres directly to the package, minimizing the use of disposable hardware and reducing landfill contributions. This makes hot melt strapping an attractive option for companies seeking to reduce their carbon footprint and promote sustainable practices.

Flexibility and Versatility

Hot melt strapping's versatility is another key advantage, particularly in compression packing applications. The molten resin can be applied in various thicknesses and widths, allowing for customization to suit different packaging needs. This flexibility enables businesses to optimize packaging solutions for specific products, ensuring maximum protection and efficiency.

Moreover, hot melt strapping can be used on a wide range of surfaces and materials, including metals, plastics, woods, and cardboards. This adaptability makes it a versatile choice for diverse industries, from automotive and manufacturing to electronics and retail.

Improved Aesthetics and Branding Opportunities

In addition to its functional benefits, hot melt strapping offers aesthetic advantages that can enhance product presentation and branding. The smooth, seamless finish of hot melt strapping provides a clean, professional look that can improve the overall appearance of packaged goods.

Furthermore, hot melt strapping can be colored or printed with company logos, branding information, or security features, providing an opportunity for businesses to differentiate their products and reinforce brand identity. This customization can also serve as an additional layer of security, making it easier to identify and track packages.

Conclusion

In conclusion, hot melt strapping stands out as a superior choice for compression packing applications due to its enhanced strength and durability, cost-effectiveness, environmental sustainability, flexibility and versatility, and improved aesthetics and branding opportunities. As industries continue to evolve and demand more efficient, sustainable packaging solutions, hot melt strapping is poised to become an even more prominent player in the market.

By leveraging the unique properties and benefits of hot melt strapping, businesses can optimize their packaging processes, reduce costs, enhance product security, and contribute to environmental sustainability. As such, hot melt strapping is not just a packaging material; it is a strategic investment in the future of efficient, reliable, and sustainable industrial packaging.