The Role of Lashing Straps in Modern Logistics and Supply Chain Management

In the interconnected world of modern logistics and supply chain management, the ability to transport goods safely and efficiently is paramount. A critical aspect of this process is the securement of cargo during transit, which ensures the integrity of goods while reducing risks to transportation personnel and equipment. Among the various tools available for cargo securement, **lashing straps** stand out as an essential component due to their versatility, reliability, and cost-effectiveness.

This article explores the pivotal role lashing straps play in the logistics and supply chain sectors, examining their applications, benefits, and contribution to global trade.

Understanding Lashing Straps

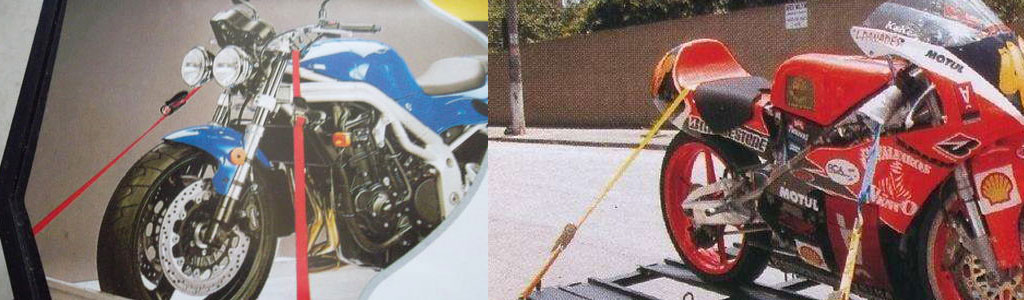

Lashing straps, also known as tie-down straps, are strong, durable bands made from materials like polyester or nylon, often equipped with ratchets or cam buckles for tensioning. They are designed to secure goods of various sizes and weights during transportation, whether by road, rail, sea, or air.

The key features that make lashing straps invaluable in logistics include:

- **High tensile strength**: Capable of handling substantial loads.

- **Versatility**: Suitable for securing a wide range of cargo types.

- **Durability**: Resistant to UV rays, moisture, and abrasions.

- **Ease of use**: Simple mechanisms for tightening and releasing.

These attributes make lashing straps an indispensable tool for ensuring the safety and efficiency of cargo movement in supply chain operations.

Applications in Logistics and Supply Chain Management

1. Securing Cargo in Transit

One of the primary uses of lashing straps is securing cargo on trucks, ships, planes, and trains. Whether it's stabilizing containers on a ship or securing pallets in a truck, lashing straps provide the necessary tension to keep goods stationary, preventing them from shifting or falling during transit.

For example, in the shipping industry, lashing straps are used to secure intermodal containers to prevent movement caused by rough seas. Similarly, in road transportation, they hold down machinery, construction materials, or even vehicles, ensuring the safety of the load and the surrounding environment.

2. Facilitating Intermodal Transport

Intermodal transport involves moving cargo using multiple modes of transportation, such as combining ships, trains, and trucks. Lashing straps play a critical role in this process by providing a uniform and adaptable solution for securing goods across different modes.

Their flexibility allows them to adapt to various cargo shapes and sizes, making them a practical choice for goods transferred between containers, flatbeds, and cargo holds.

3. Enhancing Warehouse Operations

In warehouse settings, lashing straps are often used to bundle goods, stabilize items on pallets, or secure loads during internal transport. This reduces the risk of product damage, improves inventory handling, and streamlines loading and unloading processes.

For instance, during peak logistics periods such as holiday seasons, lashing straps can ensure that high volumes of goods are moved safely and efficiently within warehouses and to distribution centers.

Benefits of Using Lashing Straps in Logistics

1. Improved Cargo Safety

Lashing straps minimize the risk of cargo movement during transit, reducing the chances of goods being damaged. By maintaining the stability of the load, these straps also enhance the safety of transportation personnel and other road users, particularly during emergency maneuvers or adverse weather conditions.

2. Cost-Effectiveness

Compared to alternatives like steel chains or specialized restraint systems, lashing straps are more affordable and lightweight. Their reusability further adds to their cost-efficiency, making them a preferred choice for businesses looking to optimize logistics expenses without compromising safety or quality.

3. Time Efficiency

The simple mechanisms of lashing straps, such as ratchets and cam buckles, allow for quick securing and releasing of cargo. This saves valuable time during loading and unloading processes, which is crucial in the fast-paced world of logistics and supply chain management.

4. Versatility Across Industries

Lashing straps can be used for various types of goods, from heavy industrial machinery to fragile consumer products. This versatility makes them a universal tool across industries, including construction, automotive, manufacturing, and retail.

5. Contribution to Sustainability

High-quality lashing straps are durable and reusable, reducing waste compared to single-use securing solutions. Additionally, many modern lashing straps are made from recyclable materials, aligning with the growing emphasis on sustainable logistics practices.

Challenges and Solutions

While lashing straps offer numerous benefits, they also come with certain challenges:

1. Improper Use

Using the wrong type of strap or not securing it correctly can lead to accidents and cargo damage. This issue can be mitigated through proper training for personnel on selecting and using lashing straps based on load requirements.

2. Wear and Tear

Lashing straps are exposed to harsh conditions, such as extreme weather and heavy loads, which can cause wear over time. Regular inspection and maintenance can extend their lifespan and ensure continued performance.

The Future of Lashing Straps in Logistics

As the logistics industry evolves with advancements in technology and sustainability, lashing straps are also experiencing innovations:

**Smart Straps**: Integrated sensors in lashing straps can monitor tension levels and alert users if adjustments are needed, improving safety and efficiency.

**Sustainable Materials**: Manufacturers are increasingly using eco-friendly materials and processes to produce lashing straps, reducing their environmental footprint.

**Customization**: Straps tailored to specific cargo types or transport requirements are becoming more prevalent, allowing for even greater versatility.

These developments underscore the continuing importance of lashing straps in supporting safe, efficient, and sustainable logistics operations.

Conclusion

In the dynamic landscape of modern logistics and supply chain management, ensuring cargo safety and operational efficiency is a top priority. **Lashing straps** play a crucial role in achieving these goals by providing a reliable, versatile, and cost-effective solution for securing goods during transit.

From facilitating intermodal transport to enhancing warehouse operations, lashing straps are indispensable across various stages of the supply chain. By addressing challenges such as proper usage and regulatory compliance, businesses can maximize the benefits of these essential tools.

As the industry embraces innovations and sustainability, lashing straps are poised to remain a cornerstone of cargo securement, supporting the safe and efficient movement of goods in a globalized economy.