Woven Strap in Action: Ensuring Safety and Stability for Your Cargo

In the world of logistics, transportation, and warehousing, the safety and stability of cargo are paramount. Improperly secured loads can lead to accidents, damage, and costly delays. Whether you're shipping goods across the globe, transporting fragile items, or moving heavy machinery, ensuring your cargo is secure and stable is essential. One of the most reliable and widely used tools for achieving this is the **woven strap**.

Woven straps are increasingly becoming the go-to solution for securing cargo in a variety of industries, thanks to their strength, durability, and versatility. In this article, we will explore how woven straps work, why they are so effective at ensuring cargo safety and stability, and the various applications in which they excel.

What Are Woven Straps?

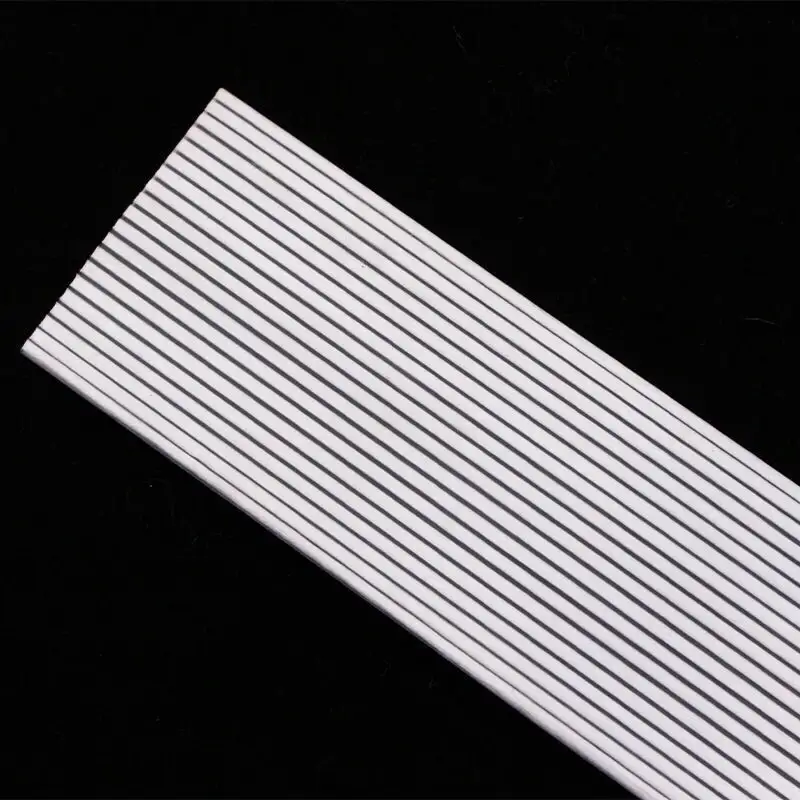

Woven straps are heavy-duty straps made by interlacing synthetic fibers, such as polyester, polypropylene, or nylon, into a tight, durable weave. This manufacturing technique increases the tensile strength and flexibility of the material, making it highly resistant to wear, tear, and stretching. Woven straps are designed to secure loads, keep items tightly bound together, and prevent shifting during transportation or storage.

Unlike traditional ropes, which can stretch and weaken over time, woven straps maintain their strength and stability under pressure. Available in various sizes, widths, and lengths, woven straps can be customized to suit different types of cargo, from small packages to large, bulky machinery. Additionally, woven straps often feature reinforced edges and UV-resistant coatings, enhancing their resistance to harsh environmental conditions.

The Importance of Securing Cargo Properly

Proper cargo securing is critical for multiple reasons. First and foremost, improperly secured loads pose significant safety risks. Shifting cargo can cause accidents, both on the road and in storage environments, leading to property damage, injury, and even fatalities. In addition, unsecured cargo increases the risk of damage to the goods being transported. Fragile items can break or get crushed, and heavy objects can cause structural damage to containers or vehicles.

Moreover, unstable loads can affect the efficiency of transportation. When cargo is not properly secured, trucks, ships, and planes are more likely to experience delays due to accidents or the need for reorganization. In industries where timing is critical, such as in global shipping or just-in-time manufacturing, these delays can result in lost profits and damaged reputations.

How Woven Straps Ensure Cargo Safety and Stability

1. High Tensile Strength

The key feature that sets woven straps apart from other binding materials, like ropes or plastic bands, is their remarkable tensile strength. Tensile strength refers to the ability of a material to withstand tension (or pulling force) without breaking. Woven straps are specifically engineered to handle heavy loads without stretching or snapping, making them ideal for securing large or bulky items.

For example, polyester woven straps are often used to secure goods that need to withstand constant tension, such as in the transport of heavy machinery or construction materials. The high tensile strength of woven straps ensures that the load remains tight and stable throughout the transportation process, reducing the risk of shifting or loosening.

2. Even Load Distribution

One of the advantages of woven straps is their ability to distribute the load evenly across the strap. The weaving process interlocks the fibers in such a way that pressure is spread out, rather than concentrated on one point. This even distribution of force ensures that no single part of the strap bears too much weight, preventing the strap from fraying or breaking under pressure.

Even load distribution also benefits the cargo being secured. It reduces the likelihood of damage to delicate or fragile items by preventing undue pressure from being applied to any one area. For example, when bundling metal pipes or securing pallets of glass, woven straps help ensure that the pressure is distributed evenly, preventing any one item from bearing too much weight or being crushed.

3. Durability and Resistance to External Factors

Woven straps are built to withstand harsh conditions, making them ideal for a variety of cargo types and transportation environments. Whether it’s exposure to UV rays, moisture, or extreme temperatures, woven straps are designed to endure. Polyester, a commonly used material in woven straps, is UV resistant, preventing it from deteriorating or losing strength when exposed to sunlight over time.

Additionally, woven straps are resistant to moisture, making them suitable for use in wet or humid conditions. In industries like shipping, where goods may be exposed to rain or sea water, woven straps offer enhanced protection against the elements, helping to secure cargo effectively in all types of weather.

These durable properties also mean that woven straps have a long lifespan. Unlike ropes or other temporary solutions, woven straps retain their integrity and strength over many uses, making them a cost-effective choice for companies that need to secure cargo on a regular basis.

4. Versatility and Adjustability

Woven straps come in a range of sizes and strengths, making them versatile and adjustable for various cargo needs. Whether securing a small bundle of boxes or a large industrial machine, woven straps can be tailored to the specific requirements of the load. They can be adjusted easily to ensure a snug, tight fit around the cargo, preventing shifting or damage during transport.

In addition, woven straps are compatible with a variety of tensioning devices, such as ratchets and cam buckles, which allow for precise adjustment. This adjustability is crucial when securing irregularly shaped or uneven loads. For example, securing a stack of pallets or a load of unevenly shaped items requires a binding solution that can be adapted quickly and easily. Woven straps, combined with the appropriate tensioning tools, provide the flexibility needed to ensure a secure and stable load.

5. Ease of Use

Woven straps are not only strong and durable but also easy to use. Unlike ropes, which require tying knots or other complex techniques, woven straps can be quickly adjusted and tightened using simple tensioning mechanisms. This ease of use is particularly important in high-pressure environments, such as in the shipping industry, where time is often of the essence.

The quick application and removal of woven straps help reduce the amount of time spent on loading and unloading cargo, thereby increasing overall operational efficiency. This makes woven straps an ideal solution for companies that need to load and unload goods quickly and safely.

Applications of Woven Straps in Cargo Securing

Woven straps are used across a wide variety of industries, from logistics and manufacturing to construction and waste management. Below are some examples of how woven straps ensure the safety and stability of cargo in different applications:

1. Shipping and Logistics

In shipping, woven straps are commonly used to secure goods in containers, on pallets, or directly on shipping vehicles. Their high tensile strength and ability to withstand harsh conditions make them ideal for international shipping, where goods may be subjected to rough handling and extreme weather. Whether securing delicate electronics or heavy machinery, woven straps ensure that goods arrive safely at their destination.

2. Construction and Heavy Equipment Transport

In the construction industry, woven straps are used to secure heavy equipment, such as cranes, bulldozers, and generators, during transport. Woven straps help keep these valuable assets stable and protected from shifting or damage while being moved between job sites.

3. Waste Management and Recycling

In waste management, woven straps are used to bundle recyclable materials like cardboard, plastic, and metal. These straps help keep the materials organized and secure during transport to recycling facilities. The ability of woven straps to endure various weather conditions makes them perfect for outdoor storage and transportation.

4. Automotive and Machinery

Woven straps are also commonly used in the automotive and machinery industries to secure components during production and transport. Whether it’s securing engine parts or entire vehicle chassis, woven straps ensure that items remain stable and undamaged throughout the manufacturing process or while being transported.

Conclusion

Woven straps are a highly effective solution for ensuring the safety and stability of cargo during transport, storage, and handling. Their superior strength, durability, and ability to distribute load evenly make them ideal for a wide range of heavy-duty applications. Whether you're shipping goods internationally, transporting construction equipment, or managing recyclable materials, woven straps offer a secure, reliable way to keep your cargo safe. Their versatility, ease of use, and long-lasting durability make them the preferred choice for industries worldwide, ensuring that goods arrive at their destination without damage and on time.